Unveiling the Superior Performance and Sustainability of PVC-O Pipes

14 November 2023With the developing advances in industrial material technologies, Oriented Unplasticized Polyvinyl Chloride (PVC-O) pipes have emerged as a high-performing and environmentally-conscious solution. This article offers a comprehensive analysis of the unique properties of PVC-O pipes that make them an industry-leading choice for a vast range of pressure pipe applications.

Defining PVC-O Pipes: Strength Derived from Deformation

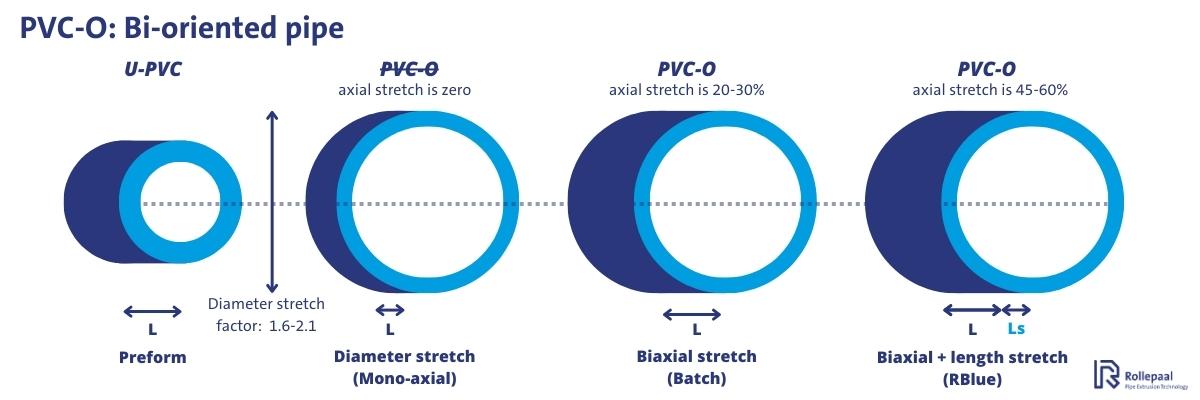

PVC-O pipes, a subtype of PVC, exhibit a unique performance characteristic - their tensile strength increases with their deformation. Enhancing the pipe diameter by 60% increases its strength from the usual 25 MPa (MRS) of standard u-PVC to 31,5 MPa. Stretching the diameter by 100% doubles your pipe's potential, bolting the strength from 25 to a whopping 50 MPa. This remarkable increase allows a potential reduction of wall thickness by 50 percent.

Standards and PVC-O: Reducing the Safety Factor

The International Organization for Standardization (ISO) recognizes the exceptional properties of PVC-O pipes, permitting a reduction in the safety factor. While a safety factor of 2 applies to standard u-PVC or PE, ISO allows the construction factor for PVC-O to be reduced to 1.4. This reduction reflects significantly on wall thickness. For instance, a 16 bar PVC-O pipe with a MRS of 50 and a construction factor of 1.4 can comply with reduced wall thickness of just 8.8 mm, leading to a substantial weight reduction of 61% when compared to u-PVC pipes.

PVC-O applies (among others) to all standards below:

- International standard ISO 16422

- the Americas standards AWWA C909 and the ASTM F1483

- the Australian and New Zealand standard AS/NZS 4441

- the Colombian standard NTC 5425

- the Brazilian standards NBR 15750

- the Indian standards IS 16647

Comparing the Hydraulic Resistance: PVC-O vs PE

The increase in strength and decrease in wall thickness significantly impact the hydraulic resistance of a pipe. If a 16 bar, 200-mm diameter PVC-O pipe is compared with a PE100 pipe, the former exhibits reduced friction and power consumption by over 50%. This advantage stems from the larger bore of the PVC-O pipe, given pipes are standardized on the outside diameter.

PVC-O Properties

Low Hydraulic Resistance of PVC-O

Stretching a PVC-O pipe on a solid mandrel results in an immensely smooth inside. This correlates to a further diminishing of hydraulic resistance when compared to offline produced PVC-O pipes or PE pipes.

Ultra-High Impact Resistance

PVC-O pipes showcase an ultra-high resistance to impact, maintaining superior strength even under extreme conditions. At room temperature, PVC-O has a five times higher impact strength than u-PVC; and even more important at -18°C (0°F), PVC still has a higher impact strength than u-PVC at room temperature. This means PVC-O pipe can be transported and installed even in freezing temperatures.

Independent investigations by the Dutch Institute Kiwa have adjudged PVC-O pipes to offer excellent resistance to water hammer effects. Moreover, their impact resistance also makes them ideal for trench technology, allowing the use of coarser backfill material, thereby lowering costs.

Flexibility and Ease of Handling

The high SDR characteristic makes the PVC-O pipe exceptionally flexible, on par with PE pipes. This flexibility facilitates the creation of large radius bends in the piping system, reducing friction. It also contributes to the pipes' manageability due to their lightweight nature, compared with heavier PE pipes.

High Earthquake Resilience

Being exposed to the ground movements during an earthquake, it's critical that pressure pipes showcase resilience. Multiple investigations, including post-earthquake studies in Christchurch, New Zealand, indicate PVC-O pipes' impressive earthquake resilience, usually escaping undamaged.

Biofilm Resistance

Resistance to biofilm's formation, a persistent issue in PE drinking water pipelines, is another significant advantage of PVC-O pipes. The inner smoothness of PVC-O pipes further minimizes the possibility of biofilm formation.

In Conclusion: Emphasizing the Superiority and Sustainability of PVC-O Pipes

PVC-O pipes set a new standard for the industry by offering distinct advantages over traditional pipe materials:

- Exceptional Mechanical Strength: The PVC-O's inherent characteristic of increased strength with deformation significantly enhances the pipe's durability and tensile strength.

- Reduced Wall Thickness and Weight: With the ISO standard permitting a reduced safety factor for PVC-O, the efficiencies in wall thickness and weight are significant, leading to logistical advantages and improved performance.

- Ultra-high Impact Resistance: PVC-O pipes showcase five times the impact resistance of u-PVC, encouraging applications in challenging conditions and environments.

- Earthquake Resilience: Proven to withstand major seismic activities with minimal damage, PVC-O pipes are a reliable choice for geologically active regions.

- Low Hydraulic Resistance: The unique manufacturing process of PVC-O pipes, involving stretching on a solid mandrel, results in a smooth interior and consequently, lower hydraulic resistance.

Given these tangible advantages, PVC-O pipes are not just an industry-leading option, but a responsible choice for a more sustainable and resilient future. The substantial benefits they offer make PVC-O pipes an essential consideration for industry professionals across the globe.

Explore the Innovative World of PVC-O: Production Processes, Technological Evolution, and Performance

Understand the PVC-O production techniques, technological advancements, and the superior performance attributes that set PVC-O apart in the industry. From the birth of bi-oriented pipes to the evolution to inline processes, and the innovative Rollepaal RBlue PVC-O production - our guide provides an informed and in-depth look into this remarkable material.

The Production Process of PVC-O: Creating a Bi-Oriented Pipe with Optimal Strength

The Evolution of PVC-O Technology: From Batch to Inline Processes

Comprehensive Comparison: PVC-O Batch Process vs. Inline Process

The Rollepaal RBlue PVC-O Plastic Pipe Production Process: Excellence in Innovation