The Production Process of PVC-O: Creating a Bi-Oriented Pipe with Optimal Strength

10 October 2023Bi-Oriented Polyvinyl Chloride (PVC-O) is a leap ahead in the PVC industry, showcasing properties that set it apart; including superior strength, robustness, and light weight. The meticulous execution of a highly precise production process is imperative for materializing these attributes. This article aims to dissect this production process, laying bare details to aid better understanding of the methods and tactics required for the manufacture of a high quality bi-oriented pipe.

The Essentials of PVC-O Production

Setting Ground with U-PVC Pressure Pipe

From a birds-eye view, a PVC-O entity is born from the manufacturing of an Unplasticized Polyvinyl Chloride (U-PVC) pressure pipe. U-PVC pipe is made by dry-blending PVC resin with additives and pigments, taking the blended material into a twin-screw extruder, and subsequently undertaking melt processing to form a homogenous and incessant pipe.

Pertinence of Temperature Control and Cooling Phase

The process of producing PVC-O products significantly rests upon exact temperature control. A stable heating phase to a temperature of 85-100 degrees Celsius (185-212 degrees Fahrenheit) is crucial to soften the U-PVC material, whereas a rapid cooling phase is essential to solidify the newly-formed molecular alignment. To sustain strict conditions throughout the process, the employment of dedicated cooling systems and temperature sensors is indispensable.

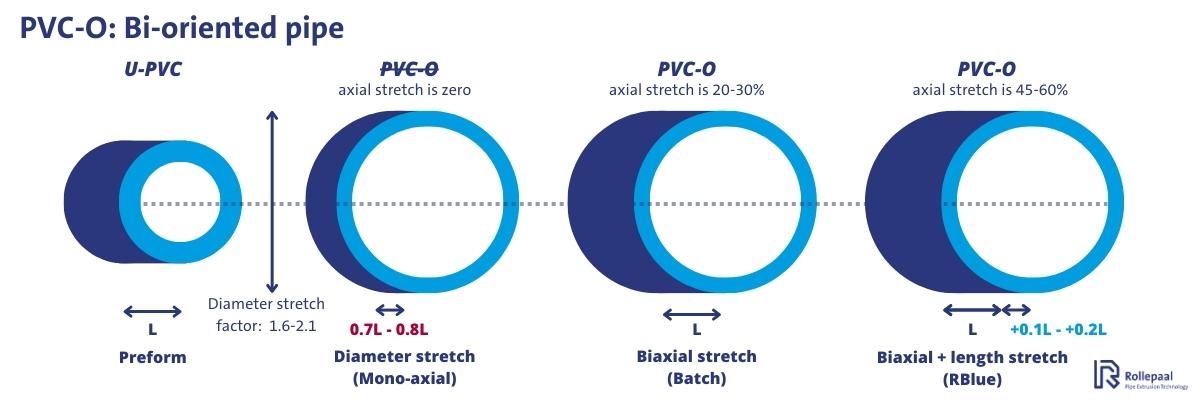

Diameter Expansion of the Pipe

At the targeted temperature, the pipe's diameter is expanded using an internal pressure or force. The required diameter stretching ratio depends on the required material strength (in ISO standards named as MRS value) and the stretching temperature. Generally, the diameter stretching ratio is between 1,6 and 2,1. Higher stretching ratios result in higher MRS values. Maintaining this expanded diameter, the pipe is subsequently cooled, freezing it into its new shape. The precise temperature control during this stage is vital for achieving the desired molecular orientation, leading to improved mechanical properties.

Orientation in PVC-O Pipe Production

The Mono Axial Stretched Pipe

By examining the molecular changes during the expansion process, we can understand the significance of orientation. If a small ring is taken from the initial pipe and stretched at the proper temperature, its weight remains the same before and after expansion. However, this process results in a reduction of both the pipe's wall thickness and its length, creating a mono axially stretched ring. Such a pipe is not an accurate representation of PVC-O, which is typically bi-oriented.

Achieving Bi-Orientation in PVC-O Pipes

To create a bi-oriented PVC-O pipe, the length of the preform must be maintained during the stretching process, while simultaneously increasing the diameter. This approach leads to an even greater reduction in wall thickness. Consequently, the orientation occurs not only in the pipe's circumference but also in the length direction.

The Rollepaal Inline Process

Rollepaal's production of PVC-O pipes is achieved through an advanced inline process developed specifically for achieving bi-orientation. Our technique guarantees constant wall thickness, optimal molecular alignment, and, consequently, outstanding product performance. Rollepaal's industry-leading techniques provide efficient and economic production of high-quality bi-oriented pipes.

The Role of Length Stretch in PVC-O Production

Bi-Oriented Pipes with Length Stretch

The Rollepaal process and other inline processes enable manufacturers to also increase the physical length of the preform during the stretching stage. In this case, the final result is a bi-oriented pipe combined with a length stretch. The strength and other properties of the pipe remain unaffected by the addition of the length stretch.

Integrated Sockets and Optimal Strength

Practical experience in sustained pressure testing has shown that creating sockets as an integral part of the pipe results in higher socket strength when the pipe includes a length stretch. A length stretch of approximately 20 percent will yield optimal strength for the integrated sockets.

Conclusion

Temperature control and orientation are crucial elements in PVC-O pipe production, ensuring optimal mechanical properties and performance. By applying precise temperature management and techniques such as bi-orientation and length stretch, manufacturers can produce high-quality PVC-O products. Rollepaal's dedication to professionalism and detail guarantees reliable and efficient solutions tailored to meet the industry's highest standards.

Explore the Innovative World of PVC-O: Production Processes, Technological Evolution, and Performance

Understand the PVC-O production techniques, technological advancements, and the superior performance attributes that set PVC-O apart in the industry. From the birth of bi-oriented pipes to the evolution to inline processes, and the innovative Rollepaal RBlue PVC-O production - our guide provides an informed and in-depth look into this remarkable material.

The Evolution of PVC-O Technology: From Batch to Inline Processes

Comprehensive Comparison: PVC-O Batch Process vs. Inline Process

The Rollepaal RBlue PVC-O Plastic Pipe Production Process: Excellence in Innovation

Unveiling the Superior Performance and Sustainability of PVC-O Pipes