Feeders & Gravimetrics: Unmatched Process Control

Discover the advanced features and benefits of Feeders & Gravimetrics by Rollepaal. Enhance your polymer processing with precision, accuracy, and efficiency.

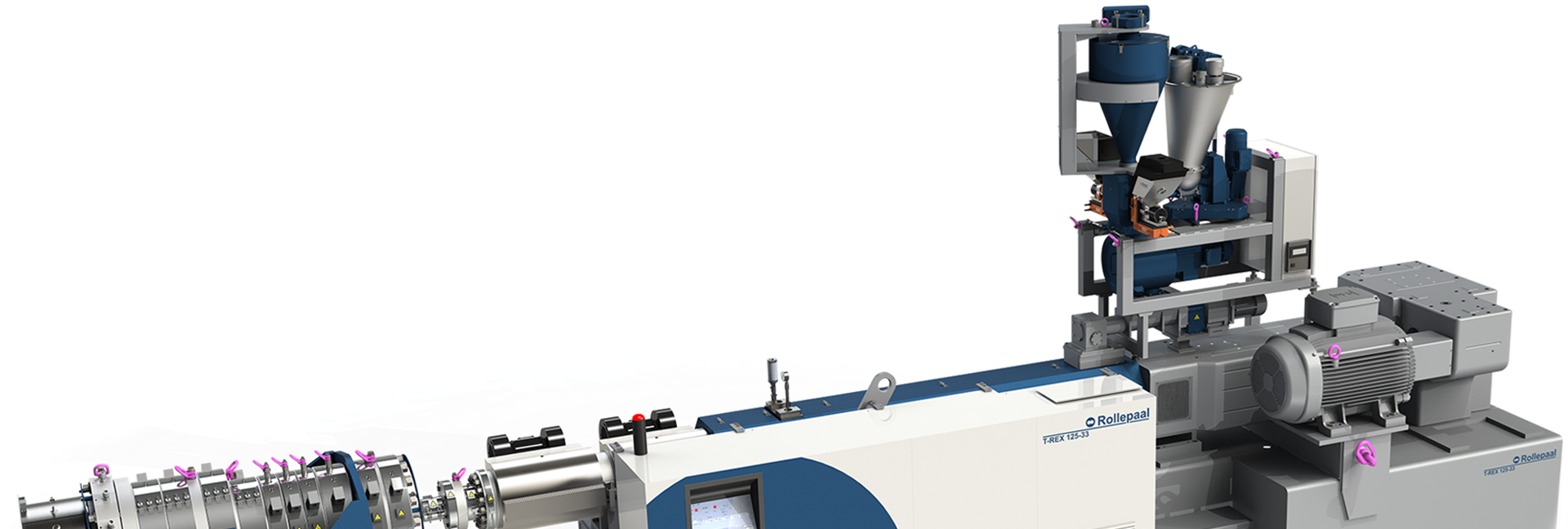

At Rollepaal, we understand the importance of precision in plastic pipe extrusion. Our Feeders & Gravimetrics leverage cutting-edge technology to give you unparalleled control and accuracy. With our comprehensive solution, you can optimize your production processes, reduce material waste, and ultimately achieve higher overall productivity.

Key Benefits:

- Improved Process Control: Our Feeders & Gravimetrics enable precise control over the amount of material being processed, resulting in consistent quality and reduced variability.

- Enhanced Efficiency: By accurately measuring and dispensing materials, our solution minimizes material waste and reduces production costs.

Ultimate Control and Efficiency with Rollepaal's Feeders & Gravimetric Solution

At Rollepaal, we offer a solution that provides the ultimate level of control and efficiency through continuous loss-in-weight measuring. This advanced technology ensures accurate dosing, with minimized waste.

Save Costs with Automatic Dosing Calibration

With the Rollepaal Gravimetric Systems (RGS) you can control the flow of material to ensure a stable extruder output regardless of fluctuations in bulk density. The automated calibration within our solution reduces overweight and ensures accurate dosing. RGS is engineered to enable a mass flow which makes your operations as efficient as possible, minimizing waste and keeping costs low.

Multi-Component Dosing: Up to Six Additives Simultaneously

Rollepaal Direct Mixing (RDM) is engineered to ensure accurate dosing of each component and to improve multi-component dosing efficiency. RDM is capable of dosing up to six additives at the same time, PVC resin and the necessary additives can be mixed directly on top of the extruder, meaning no need for a mixing plant.

Easy to Operate and Clean

Our solution is engineered for ease of operation and maintenance, reducing downtime and optimizing productivity. Cleaning and operating our Feeders & Gravimetrics is quick and easy, ensuring maximum uptime to meet customer needs. The user-friendly interface, moreover, ensures quick and intuitive operation, reducing the time needed for operator's training.

Connected with integrated software

Furthermore, our Feeders & Gravimetrics are connected with a centralized and integrated software system, simplifying operational management. Operators have seamless control of the system, thereby optimizing productivity while keeping costs low and plant managers satisfied.

Color Additive Stability: Results Guaranteed

Our Feeders & Gravimetrics are designed for maximum stability in color additives. We understand the importance of consistency in polymer processing, and our solution delivers reliable and consistent results, satisfying pipe producers needs with confidence.

Additional benefits

- Improved Pipe Quality: With precise material control, our Feeders & Gravimetrics ensure consistent pipe quality, and reduce defects.

- Cost Savings: By minimizing material waste and optimizing production processes, our solution helps reduce material costs.

- Competitive Edge: The accuracy and efficiency offered by our Feeders & Gravimetrics give you a competitive advantage in the industry, enabling you to meet customer demands.

Specifications

- Rollepaal Direct Mixing (RDM): the next step in processing. PVC resin and the necessary additives can be mixed directly on top of the extruder, meaning no need for a mixing plant

- Rollepaal Direct Addition (RDA): this unit is mounted on the extruder for constant dosing of hard-to-handle materials in an industrial environment (e.g. CaCO3)

- Rollepaal Gravimetric Systems (RGS): control the flow of material to ensure a stable extruder output regardless of fluctuations in bulk density

- RGSF: a single screw feeder designed for free-flowing materials such as granules and prills

- RGDF 4: a self-wiping double screw feeder designed for dosing non-free-flowing sticky powders

Product Sheet Cost Saving Solutions

Download our product sheet with Cost Saving Solutions with information about our Feeders & Gravimetrics solution. Download our product sheet here.

Contact us

________________________________________________

Ready to enhance your polymer processing with Feeders & Gravimetrics solutions from Rollepaal? Fill out the form to inquire about the products, request a quote tailored to your specific requirements or schedule a consultation with our extrusion experts. Take the first step towards achieving exceptional quality and efficiency in your production.