Pipe Cutters: High-Quality Cutting Solutions

Our cutters provide highly accurate and dependable cutting solutions, ensuring optimal results for your operations.

High-Quality Pipe Cutters & Chamfering Machines

At Rollepaal, we offer a wide range of pipe extrusion cutters that are reliable, and easy to use. Our cutting solutions are designed to meet even the most demanding requirements of your production process, providing you with high-quality results and increased productivity.

Key Benefits:

- Precision: Our pipe cutters offer accurate cutting that deliver consistent and consistent results every time.

- Efficiency: Our cutting solutions are designed to improve your productivity by reducing downtime and increasing throughput.

- Durability: Our cutters are built to last, constructed with high-quality materials that can withstand the rigors of any extrusion process. Moreover, they are easy to maintain, saving you time and money on repairs.

- Versatility: Our cutters can handle a variety of materials, from pipes to profiles, making them the perfect solution for any extrusion process.

Dust Free and Clean Production

With our dust-free cutting solutions, you can ensure that your production process stays clean and free of harmful contaminants. Our pipe extrusion cutters are equipped with state-of-the-art features that allow for dust-free cutting, making them perfect for industries where cleanliness is crucial. By choosing a cutters from Rollepaal, you can guarantee a clean and safe production process.

Tool Change During Production

Rollepaal's pipe cutters are designed for quick and easy tool changes, making them perfect for companies where fast production is paramount. With our cutting solutions, you can swap tools during the production process, without the need for extended downtime.

Suitable for High-speed Lines, PP/PVC Pipe, High-filled Materials and PVC-O

Rollepaal's pipe cutters offer versatile and reliable cutting solutions for high-speed lines, PP and PVC pipe, high-filled materials, and PVC-O. Our cutting solutions are designed to work with a wide range of materials and applications, providing you with precise and consistent results every time.

No Exchange Parts Needed When Changing to a Different Pipe Size

Rollepaal's pipe cutters are designed to change to a different pipe size quickly and easily, without the need for exchange parts. You can switch between pipe sizes with ease, saving you time and money on unnecessary parts and tools.

Touch Screen Control Panel

Our pipe cutters feature a touch screen control panel, which allows for an easy and intuitive operation. With our user-friendly control panel, you can control and adjust your cutting solutions with ease, giving you full control over your production line.

Low Noise

Rollepaal's pipe cutting solutions are equipped with features that reduce noise to a minimum, creating a quieter production environment for your workers.

Integrated Software in the Central Controls

With our cutting solutions, the software is seamlessly integrated into the central controls, allowing for a streamlined operation process. The software is designed to be efficient and easy to operate.

Usable on Other Production Lines

Rollepaal's pipe extrusion cutters are designed to be versatile and adaptable. They work reliably with a wide range of materials and applications and stay efficient, even when working with different production lines.

Adjustable Contact Pressure

Our pipe cutters are equipped with adjustable contact pressure, allowing for precise cutting control. You can control the pressure applied to your material during the cutting process, ensuring that you get precise, clean cuts every time.

Storage of Pipe Setting in the Controller

Rollepaal's pipe cutters go beyond the standard features with their advanced controller capabilities, enabling precise and consistent pipe settings storage in the controller for seamless production efficiency.

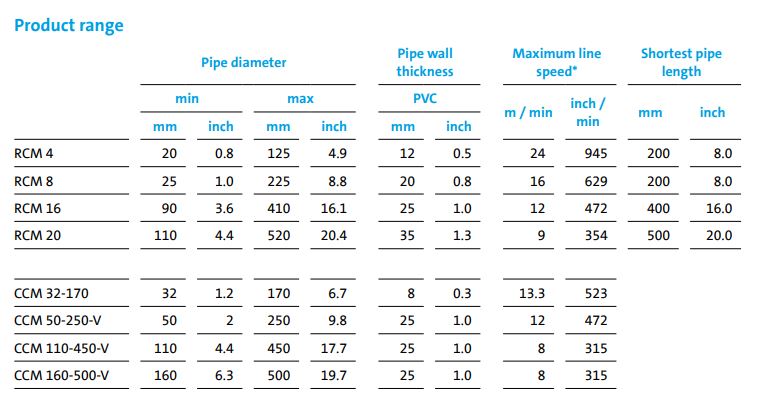

Product Range

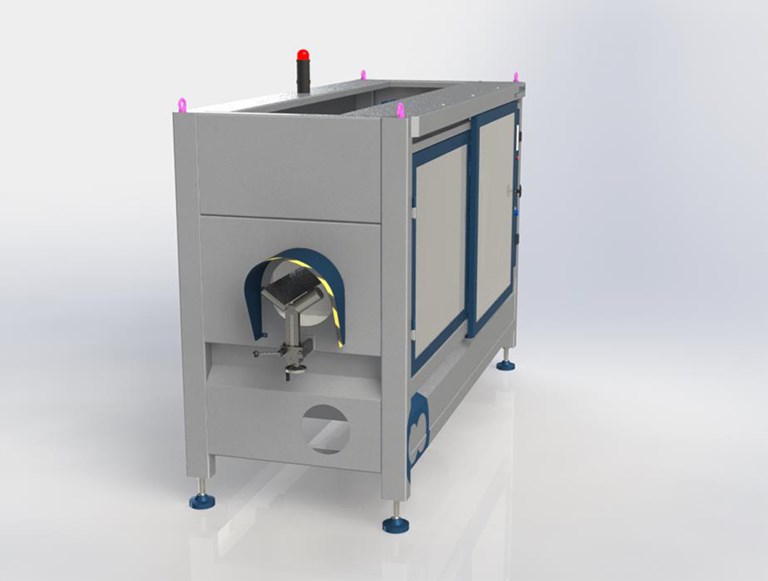

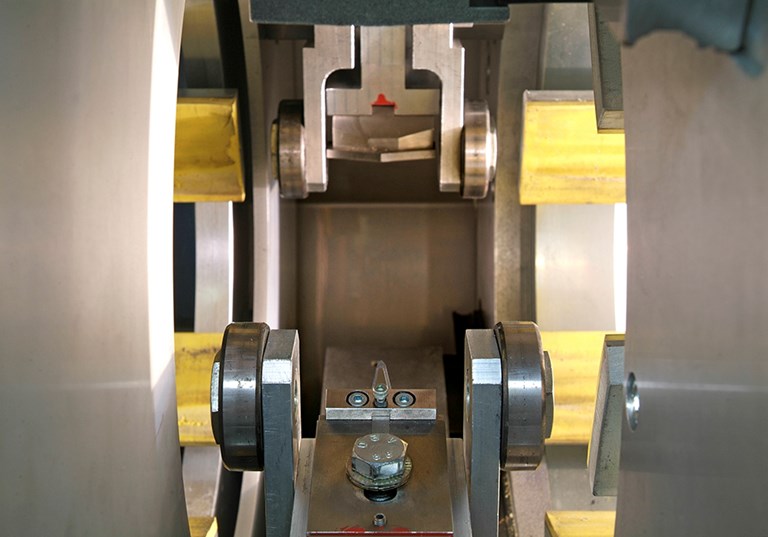

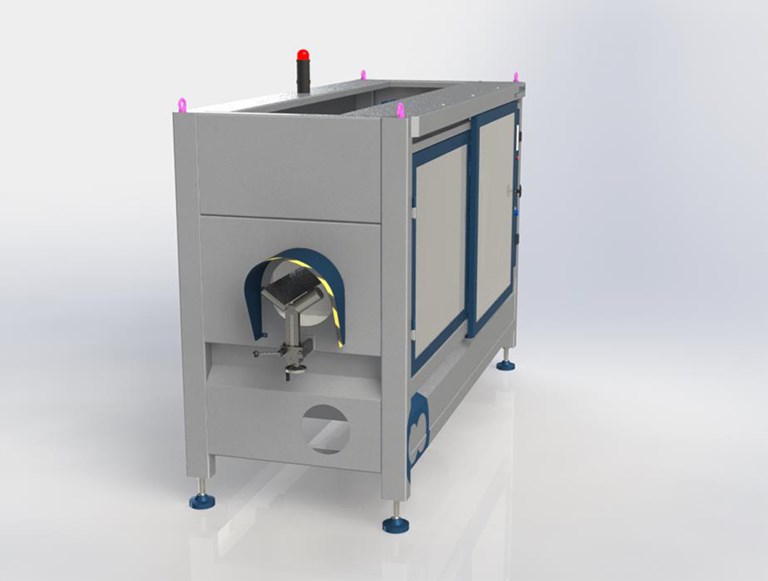

We offer comprehensive range of cutters and chamfering machines (CCM & RCM). These machines are designed with unique mechanisms to ensure optimal performance across a spectrum of diameters, ranging from 20 to 520mm (3/4" - 20"). Ingenious incorporation of chisel cutting devices allows precise rotations around the pipe, rendering a dust free, clean cut.

Cutting & Chamfering Machine - CCM:

The CCM is a modular automatic cutting and chamfering solution designed for plastic pipes within diameter range of 32 to 500mm (1 ¼"-20"). Rollepaal's CCM elevates the cutting efficiency by harnessing the synchronization between the pneumatically actuated clamp assemblies and the pipe movement, thereby enabling uninterrupted production. The tool movements and carriage in the CCM are operated by a camdisk, promoting a seamless transition from one pipe to the next, without necessitating changes in components.

Rollepaal Cutting Machine - RCM:

The RCM offers precise cutting and chamfering for plastic pipes within diameter range of 20 to 520mm (3/4"- 20"). With peculiar attention to minimize conversion and cycle time, the RCM ensures smooth ejection of cutting swarf through advanced technology, rendering it agnostic to irregularities in the pipe shape. The RCM, controlled through a camdisk, offers dust-free production, easy operation, robust design, and is ideally suited for PP, PE, PVC and high-filled materials.

Rollepaal's pipe cutters range in size from Ø20-Ø520mm, ensuring precise and reliable performance for a wide range of applications. Our machines are engineered with industry standards in mind, delivering exceptional accuracy and meeting the needs of our customers.

Product Sheet Pipe Cutters

Explore the technical specifications of our Pipe Cutters and unleash their potential in your extrusion process. Download our product sheet here.

Contact us

________________________________________________

Ready to enhance your extrusion process with our Pipe Cutters? Fill out the form to inquire about the product, request a quote tailored to your specific requirements or schedule a consultation with our extrusion experts. Take the first step towards achieving exceptional quality and efficiency in your production.