Upgrade

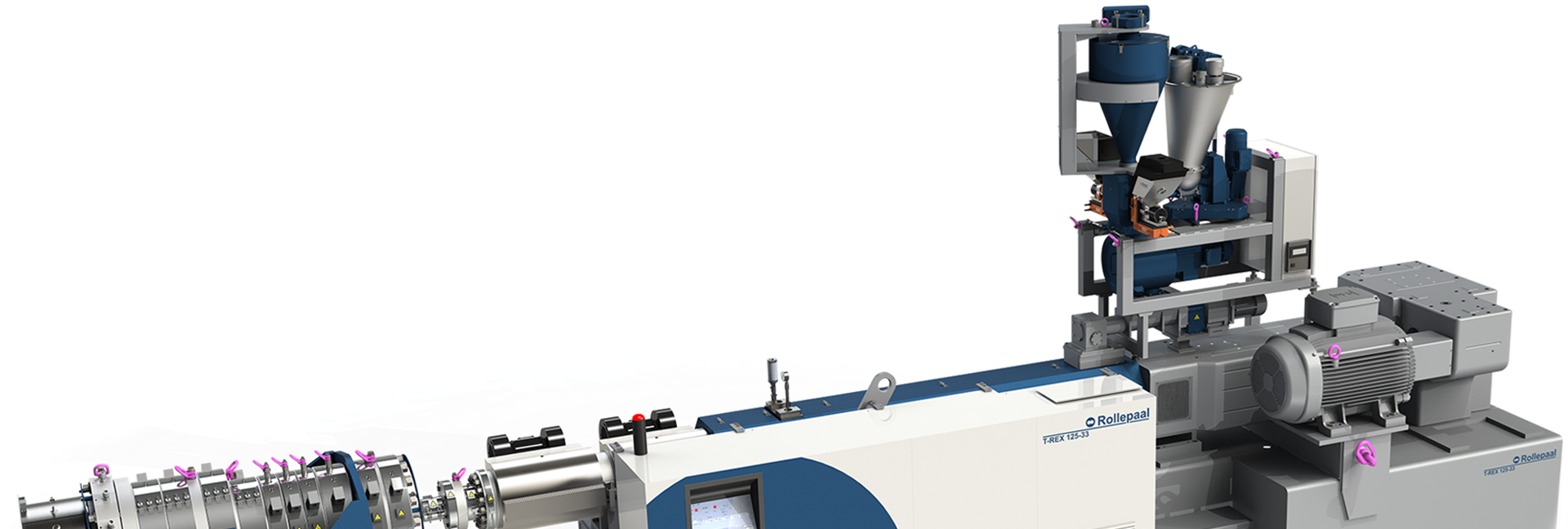

At Rollepaal, we offer a comprehensive range of upgrades for your plastic extrusion machinery. Our upgrades are designed to optimize performance, increase efficiency, and improve product quality.

Let's take a closer look at particular upgrades that we do:

- Upgrade of the gravimetrically hopper:

Rollepaal upgrade for the gravimetrically hopper includes advanced sensors and control systems that ensure precise and accurate material feeding. This upgrade optimizes material usage and reduces waste, resulting in cost savings and improved product consistency.

- Upgrade of the extruder control systems:

Rollepaal extruder control system upgrade incorporates state-of-the-art technology to enhance process control and monitoring. This upgrade enables precise control of parameters such as temperature, melt pressure, and screw speed, ensuring consistent product quality and minimizing production downtime.

- Upgrade of the extruder plasticization unit (updated screw design):

Rollepaal upgrade for the extruder plasticization unit involves a redesigned screw to enhance plastic melting and mixing. This upgrade improves plasticization efficiency, reduces energy consumption, and results in enhanced melt quality for better extrusion performance.

- Upgrade of cooling tank level and temperature controllers:

Rollepaal upgrade for cooling tank level and temperature controllers includes advanced sensors and control algorithms to maintain accurate and stable cooling conditions. This upgrade ensures consistent product dimensions and minimizes cooling-related defects, resulting in improved product quality.

- Upgrade of wall thickness measurement scanners:

Rollepaal upgrade for wall thickness measurement scanners utilizes high-precision sensors and advanced data processing algorithms. This upgrade enables real-time monitoring of wall thickness variations, ensuring product compliance with specifications and reducing material waste.

- Installation of processing parameters data logging:

Rollepaal data logging installation upgrade involves the integration of a comprehensive system to record and store important processing parameters. This upgrade enables you to analyze and track process variables, facilitating process optimization, troubleshooting, and quality control.

- Periodically analyzing of processing parameters:

We offer periodic analysis services to evaluate your processing parameters and identify opportunities for optimization. Our experienced technicians analyze data collected from your machinery and provide detailed reports with recommendations for improved efficiency and product quality.

By investing in these upgrades, you can benefit from enhanced control, improved product quality, reduced waste, and increased production efficiency. Our team of experts at Rollepaal is ready to assist you in selecting and implementing the upgrades that best meet your specific needs.

Contact us today at helpdesk@rollepaal.com to discuss your requirements and take your plastic extrusion operations to the next level.